Stainless steel sheet is a metal material widely used in several industries, including construction, automotive, medical equipment and kitchenware. Due to its excellent corrosion resistance, heat resistance and strength, stainless steel sheet is the material of choice for many engineering projects. At the same time, stainless steel materials have an easy-to-clean surface, can be recycled and reused, and have an irreplaceable role in the food and medical industry.

There are ten common surface types, they are No. 1, 2B, BA, No. 4, HL, 6K, ordinary 8K, fine grinding 8K, 8K+HL, sandblasting. Different surface states are suitable for different scenarios, Jiangsu Tisco Tianguan Metal Products Co., Ltd. introduces you the different applications and differences of these different surface states, so that you can use them as a reference when purchasing and using stainless steel materials.

|

Surface Type |

Description |

Characteristics |

Common Applications |

|

No. 1 |

Hot-rolled, heat-treated, and pickled surface |

Rough, unpolished |

Industrial uses, structural parts, welding applications |

|

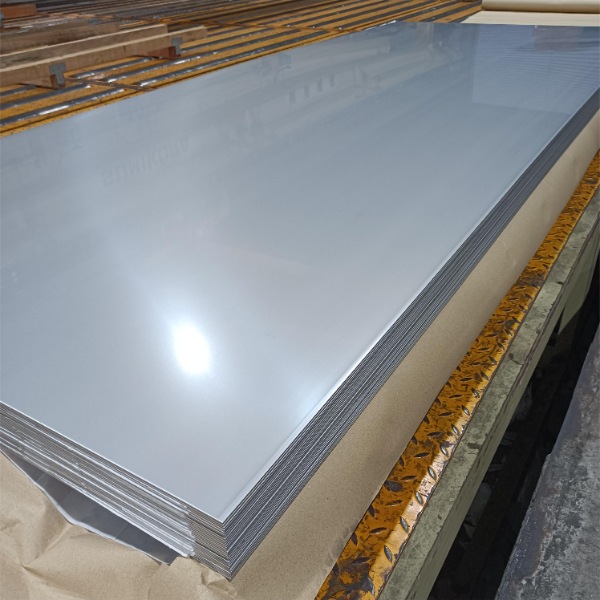

Cold-rolled, annealed, pickled, and lightly rolled |

Smooth, matte finish, easy to clean |

Kitchen equipment, architectural decor, medical equipment |

|

|

Bright annealed reflective surface |

High gloss, near-mirror finish |

Decorative uses, appliance surfaces, food and chemical processing equipment |

|

|

No. 4 |

Polished with 180-240 grit abrasive material |

Fine light-textured polish, refined look |

Architectural decoration, kitchen equipment, elevator interiors |

|

HL |

Hairline finish created by grinding |

Linear texture, adds visual depth, decorative effect |

Decorative panels, architectural facades, elevator interiors |

|

6K |

Semi-mirror polish |

High gloss but not as reflective as 8K |

Architectural decoration, decorative applications |

|

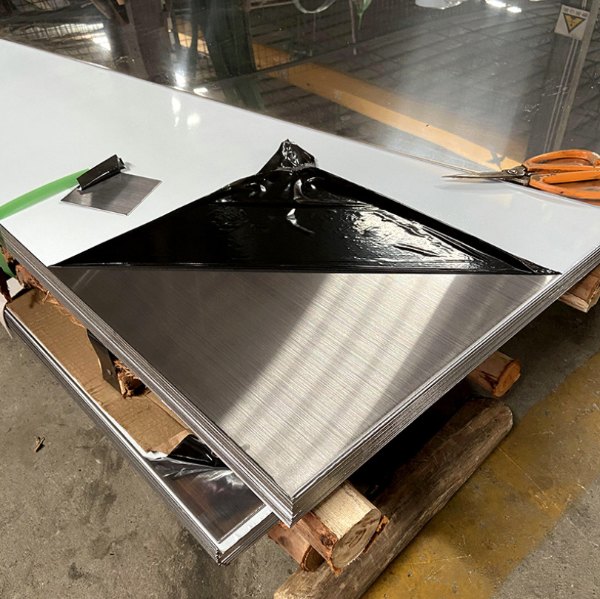

Regular 8K |

Standard mirror finish |

Very high reflectivity, mirror effect |

High-end decorative panels, furniture, elevators |

|

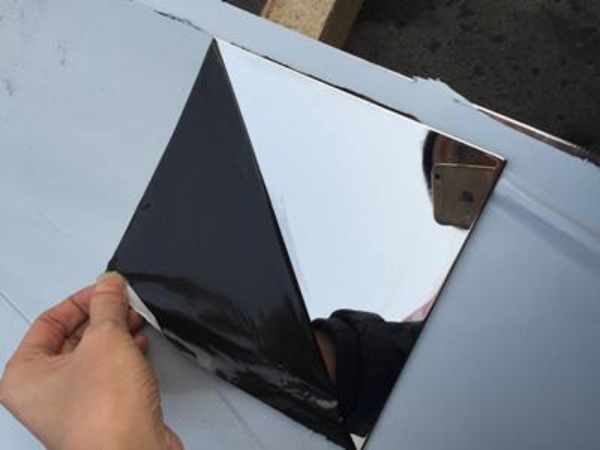

Super 8K |

Advanced mirror finish with finer polishing |

Excellent mirror gloss, clear reflection |

Luxury architecture and decor, artworks, display items |

|

8K+HL |

Combination of 8K mirror and hairline finishes |

High gloss of mirror with texture of HL |

High-end architectural decor, special decorative effects |

|

Sandblasted |

Surface treated by blasting with sand |

Uniform fine matte texture |

Appearance decoration, anti-slip treatment, enhanced wear resistance and aesthetic appeal |