Stainless steel decorative plates have gained increasing popularity in various fields such as construction, home decoration, arts and crafts, electronics, and automotive decor due to their unique blend of aesthetics and functionality. In this article, we will explore the primary classifications of stainless steel decorative plates.

Stainless steel decorative plates come in a variety of colors. Common ones available in the market include pink, brown Japanese gold, green, titanium black (black titanium), champagne gold, bronze, titanium white, purple-red, sky blue, rose gold , emerald green, bronze, titanium, and colorful options, among others.

Electroplating Method: This process involves depositing a metal film onto the surface of metal or other materials through electrolysis. It serves purposes like corrosion resistance, improved wear resistance, electrical conductivity, and aesthetic enhancement.

Water Plating Method: This method relies on the reduction of metal ions in a water solution to form a metal coating on the surface.

Fluorocarbon Paint Method: In this process, a coating primarily composed of fluororesin is applied to the metal surface to create a protective and decorative coating.

Spray Painting: This technique uses compressed air to atomize paint, which is then applied to the surface of stainless steel plates, resulting in a variety of colors.

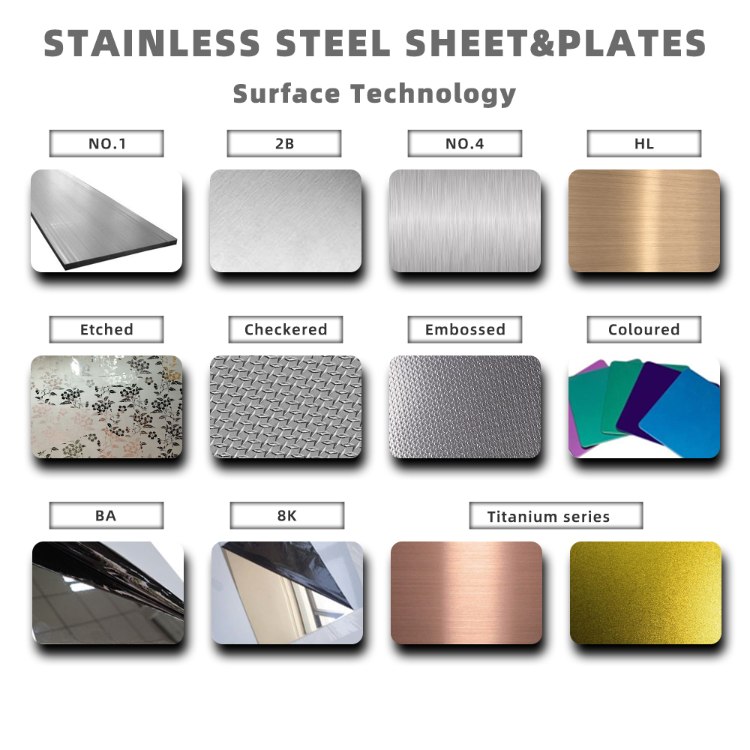

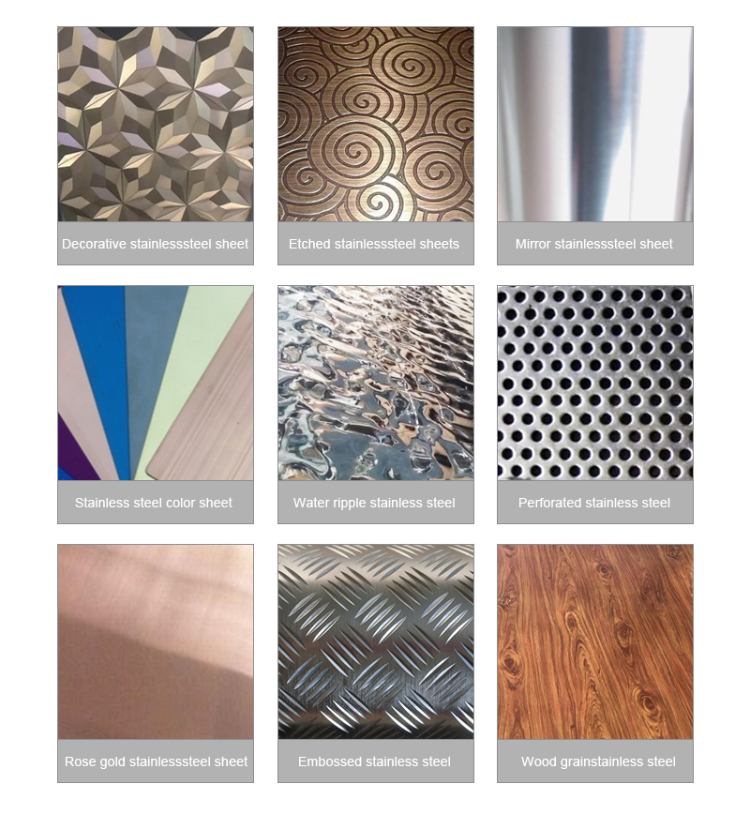

Stainless steel decorative plates are divided into several types based on their surface texture:

Composite plates

Etched plates

Sandblasted plates

Mirror plates (8K)

Embossed plates

Frosted plates

Patterned plates

Brushed plates

The mirror panel, often referred to as an 8K plate, is created by polishing the stainless steel plate surface with abrasive liquid and polishing equipment to achieve a mirror-like finish. Subsequently, it undergoes electroplating and coloring processes.

Colored Stainless Steel Brushed Plate:

The brushed plate, also known as a hairline pattern, gets its name from its hair-like surface texture. This texture is created through wire-like patterns on the surface and is produced using oil-polishing hair texturing machines. The surface is matte, offering wear resistance superior to regular bright stainless steel. It also imparts a higher-grade appearance.

This type is created by processing the stainless steel plate surface with mechanical equipment and zirconium beads. The result is a fine, bead-like sand surface, resulting in a distinctive and unique decorative effect after electroplating and coloring.

This type combines various processing methods such as coating, sandblasting, hairline polishing, etching, and more on the same stainless steel plate. Electroplating and coloring are typically the final steps to achieve the desired look.

Grained and brushed plates, despite being both matte, offer different surface conditions and appearances. The grained board features a sand pattern composed of circular patterns, appearing irregular and random when viewed closely.

Etched plates are created by employing various chemical methods on base plates, such as sandblasted plates, mirror plates, or brushed plates. These methods result in patterns like Japanese texture, wire drawing, gold inlay, and titanium gold, exhibiting intricate and visually striking designs .

These classifications offer a comprehensive understanding of the versatile world of stainless steel decorative plates, enabling their suitable use in a wide range of applications.

More Knowledge About Stainless Steel

Processing procedures and applications of stainless steel plate mirror and hairline effects

Performance and Applications of Common Stainless Steels

What is the difference between stainless steel 1Cr18Ni9Ti (321) and 0Cr18Ni9 (304)