Cutting: First, the stainless steel plate may need to be cut according to specific size requirements, which can be done by shearing, cutting machine or laser cutting.

Grinding: Each cut edge needs to be ground to ensure a smooth edge.

Polishing: The key to a mirror effect is polishing. This can be achieved by methods such as mechanical polishing, electrochemical polishing or chemical mechanical polishing. Polishing removes imperfections and scuffs from the stainless steel surface while providing a highly reflective mirror finish.

Cleaning: Clean the stainless steel plate to remove residue and dirt generated during the polishing process.

Note: During this process, do not rub the polishing wax onto the covering film on the surface of the workpiece, and be careful not to damage the covering film.

Polishing is the last stage of mirror polishing. Use a clean cotton cloth wheel to rub on the surface of the workpiece after mirror polishing. Wipe clean and polish the stainless steel plate workpiece after all previous processes have been completed. The function of this process is that no welding traces can be discerned on the surface of the stainless steel plate, and the waxed and polished workpiece is polished. The brightness reaches a mirror reflection high of 8k, and the polished and unpolished parts of the workpiece are basically visible. No difference is made, thus achieving a complete mirror effect.

The stainless steel plate with mirror effect is also called 8K plate. It is polished on the stainless steel plate surface by polishing equipment through grinding liquid, so that the surface brightness of the stainless steel plate is as clear as a mirror. Mainly used in stainless steel series products such as construction, elevators, industry and facility decoration.

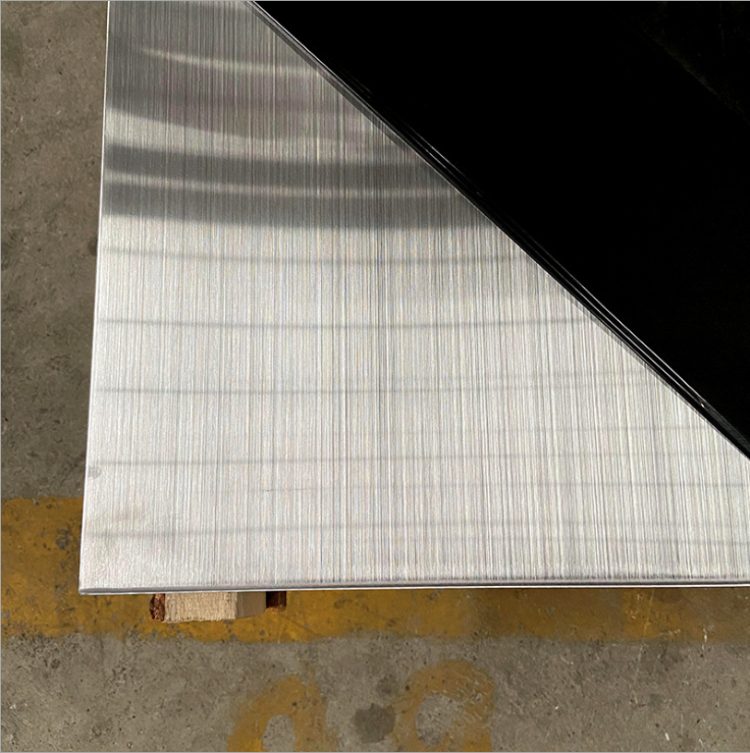

In addition to the mirror effect, the surface of stainless steel plate also has a hairline effect. There are many kinds of hairlines, including hairline, snowflake sand, harmonious, cross, and cross grains. All textures need to be polished with oil. The pattern machine is processed according to the requirements. They are also mostly used for decoration, among which stainless steel champagne gold and pattern plates have better decorative effects.

Pickling: Stainless steel plates are usually pickled in an acidic solution to remove the oxide layer, scale and rust to prepare them for hairline processing.

Hair lines: Hair lines are achieved through methods such as mechanical methods (rolling or embossing), chemical methods (etching hair lines), or laser processing, which will form a pattern or texture on the surface of the stainless steel.

Cleaning: Clean stainless steel plates to remove residue and dirt from processing.

Specifically, oil-milled straight hair is mainly used for architectural decoration, elevators, building doors and panels, etc.; oil-polished hair is used for elevators, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment, etc. , dry hair is used in home appliances, elevators, kitchen equipment, decorative materials, etc.

More Knowledge About Stainless Steel

Related introductions about stainless steel pipes

Performance and Applications of Common Stainless Steels

Brushed stainless steel plate in the process of processing points of attention