Commonly used materials for colored stainless steel plates include 201 stainless steel and 304 stainless steel. Among them, 304 stainless steel plate has higher corrosion resistance than 201 stainless steel plate, and the original material is smoother and brighter than the rolled material. Because of the large price difference, many merchants pass off inferior quality products, using rolled materials as genuine materials and 201 as 304. Therefore, the first task during inspection is to verify whether the plate is made of the specified material. Jiangsu Tisco Tianguan Metal Products Co., Ltd. has always used genuine materials and can accept customers to visit and inspect the factory. It is also acceptable for customers to arrange for third-party testing agencies to come to the factory for testing. It is our principle to insist on using genuine products, and we look forward to cooperating with everyone.

201 and 304 can be distinguished by testing chemicals, while the original material and the calendered material can be distinguished mainly by observing the quality of the board surface. The surface of the original material board is smooth and flat, the color is uniform, the brightness is high, and the thickness of the entire board is consistent, while the calendered material The surface of the board is dark, uneven in color, often black or streaked, with defects such as roller-imprinted blisters on the back and peeling watermarks. The thickness difference of the board can reach 2 to 3 lines.

However, with the improvement of production processes and technologies in many large-scale rolling mills, the gap between genuine materials and rolled materials is slowly narrowing. Some imitation genuine boards can even be fake, and it requires professionals with rich experience to distinguish them.

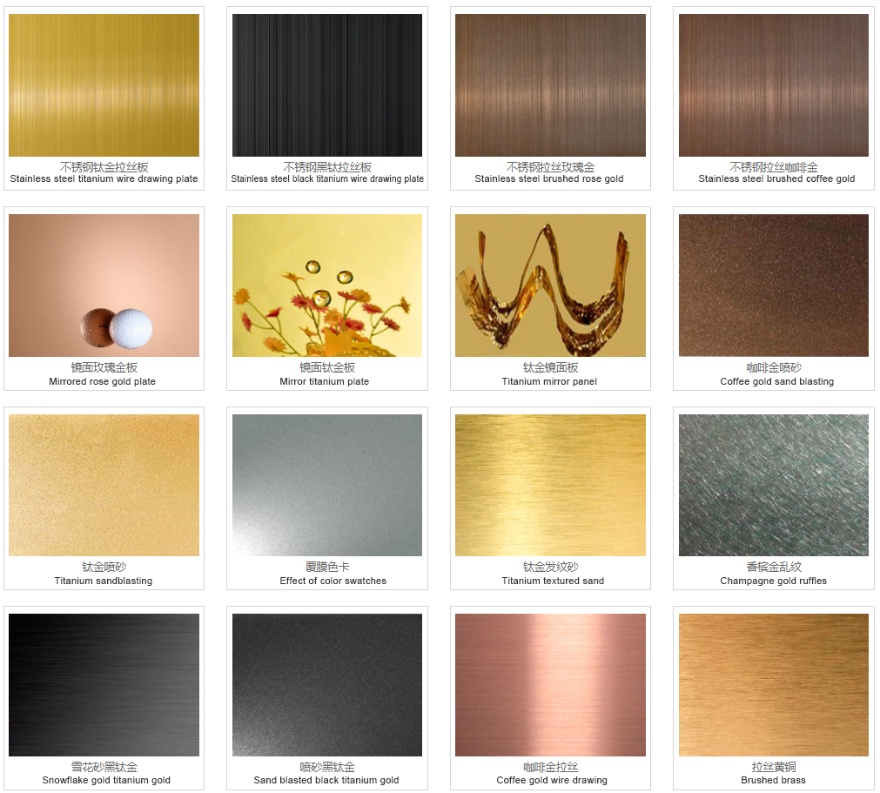

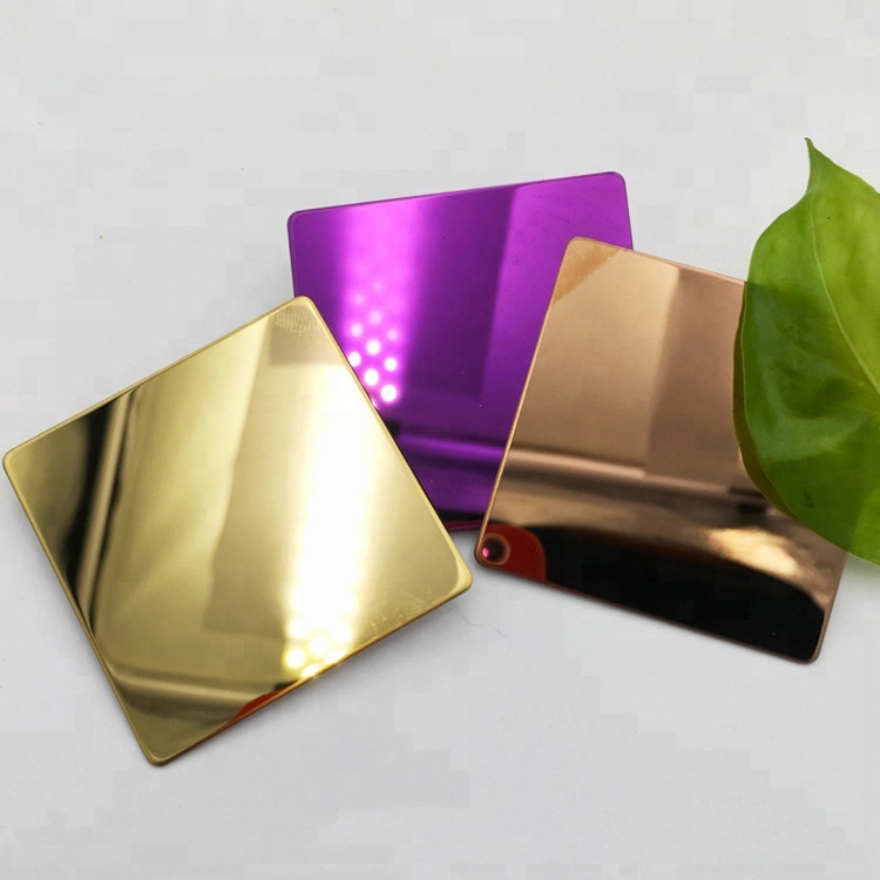

Colored stainless steel plate is mainly used in the field of decoration, which has high requirements on the ornamental and decorative properties of the plate surface. A good-colored stainless steel plate should have no color difference visible to the naked eye under direct sunlight, and the entire batch of plates should have no color difference, uniform coloring, good color, no scratches, no bending, and no fading. The surface of the stainless steel mirror panel should be free of scratches and horseshoe marks and have high brightness.

The colored stainless steel plate will be affixed with a protective film before leaving the factory. Many slow-selling boards have been left in warehouses for a long time, and the protective film has become powdery and difficult to tear. After tearing, there is still a lot of glue stuck to the surface of the board, which is ugly and difficult to remove, which is time-consuming and labor-intensive.

Even if it is a transparent film, when inspecting the goods, you must tear off a large piece to see the quality of the film. If you need to cut and bend it later, it is best to apply a protective film of 6C or above first to avoid scratching the board surface. After the colored stainless steel plate is installed, the film layer should be peeled off as soon as possible to avoid staining with glue. Especially for outdoor decoration, it is best to tear off the protective film immediately after construction due to direct sunlight.

The above is about how to identify the quality of colored stainless steel plates from three aspects: material, effect, and film. If you are interested in colored stainless steel plates, please follow our company and we will update you with relevant knowledge regularly.

More Knowledge About Stainless Steel

Introduction to stainless steel decorative plates

Performance and Applications of Common Stainless Steels

How to distinguish between 202 stainless steel and 304 stainless steel