Stainless steel perforated plate is a metal plate with a hole pattern, usually made of stainless steel. It has the characteristics of an arrangement of holes through a fine manufacturing process. It is widely used in applications such as filtration, screening, ventilation and decoration. The most common stainless steel grades used for perforated panels are 304 and 316 because of their excellent corrosion resistance.

The first step in manufacturing stainless steel perforated plate is to select the stainless steel plate suitable for the specific requirements. Due to stainless steel's corrosion and heat resistance properties, 316 stainless steel is often chosen for higher corrosion resistance applications. Make sure to choose a stainless steel plate of appropriate quality and thickness to ensure the durability and performance of the perforated plate.

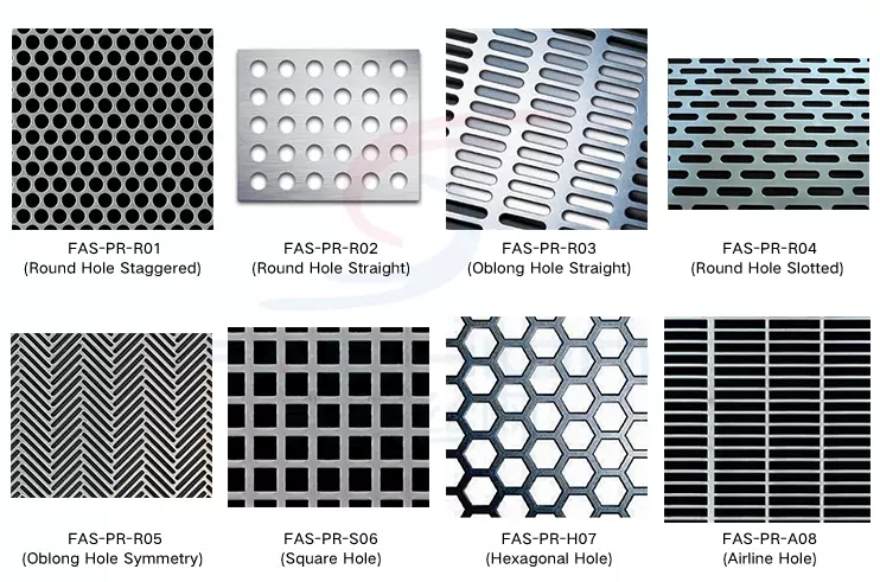

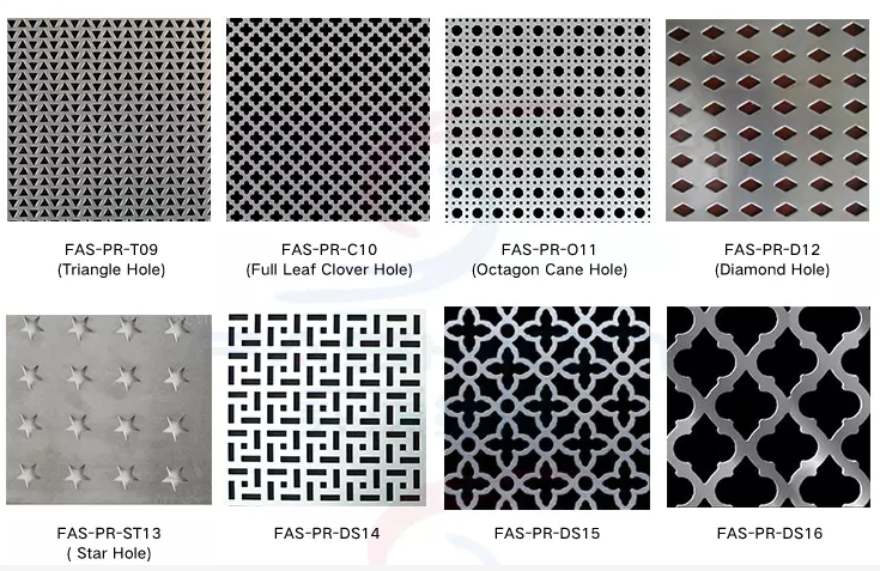

Based on specific application requirements, designers need to create a perforated plate's hole arrangement pattern. These patterns can include various sizes, shapes and arrangements of holes to serve filtering, ventilation, screening or decorative purposes. Pattern design is a critical step in stainless steel perforated plate manufacturing as it determines the appearance and functionality of the final product.

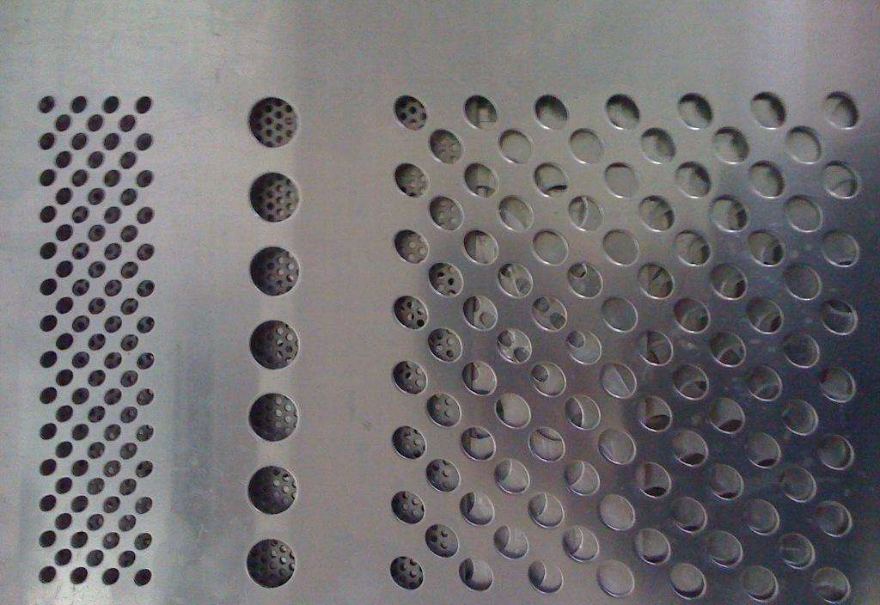

After completing the pattern design, the manufacturing process enters the punching processing stage. Specialized equipment such as punch presses or CNC presses are used to punch holes in the stainless steel plates according to the designed pattern. This step requires high precision to ensure that the distance between the holes and their dimensions are accurate. Punching is usually done on the flat surface of a stainless steel plate, but complex three-dimensional patterns can also be created by controlling the movement of a punch.

After punching is completed, the stainless steel perforated plate can be further reshaped and bent, cut or formed as needed. This helps adapt to different applications such as making screens, guardrails or decorative panels. Shaping processing often requires the use of specialized equipment, such as bending machines or cutting machines, to ensure the accuracy and consistency of the panels.

In order to improve the appearance and increase corrosion resistance, stainless steel perforated plates are usually surface treated. This includes polishing, pickling or other chemical treatment processes to make the surface of the stainless steel plate smoother, more uniform and shiny. Surface treatment also helps reduce the risk of stains and corrosion, thereby extending the life of stainless steel perforated plates.

Finally, the manufacturer conducts quality inspection of the finished product to ensure that the perforated plate meets specifications and quality standards. After passing inspection, the perforated plates will be packaged in custom sizes and shapes for shipping and installation to avoid damage and maintain product integrity.

Jiangsu Tisco Tianguan Metal Products Co., Ltd. is a manufacturer with its own factory, capable of producing stainless steel perforated plates in various sizes according to customer requirements. We are committed to providing high-quality stainless steel perforated plate to every customer. If you have purchasing needs, please feel free to send us drawings.

More Knowledge About Stainless Steel

Characteristics and applications of TP316 and TP316L stainless steel tube