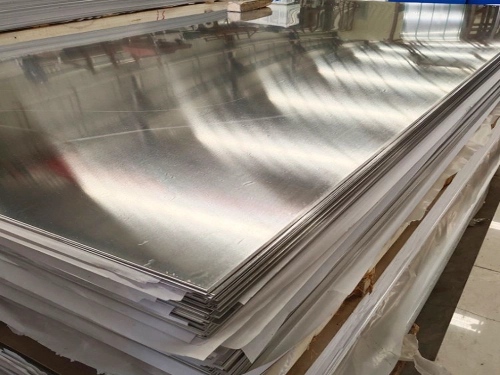

The hot-rolled stainless steel plate manufacturing process involves heating slabs, rough and finishing rolling, and subsequent processing to produce steel plates with characteristics such as poor toughness, surface imperfections, and a lower cost. Advantages of hot rolling include refining the steel structure, eliminating microstructural defects, and improving mechanical properties. However, disadvantages include the potential for delamination due to pressed non-metallic inclusions, and residual stress caused by uneven cooling, impacting steel performance under external forces. Hot-rolled stainless steel plates find widespread use in civilian applications despite their inferior mechanical properties compared to cold working or forging.

Read More